Wienerberger Announces Investment of INR 30 Crore in its Factory in Kunigal

Wienerberger AG, the € 3.3 bn global player in the construction sector, announces to invest INR 30 crore in their Kunigal factory, located in the Tumkur district of Karnataka. The announcement was made by Christof Domenig, CEO, Wienerberger Building Solutions, Wienerberger AG on the company’s 200th anniversary and the 10th anniversary of operating in India at Wienerberger’s factory in Kunigal. The investment will enable the company to support its expansion plans including an upgrade and an implementation of new equipment in the factory, converting to natural gas as a fuel and launch of new building solutions that will enable construction practices to be simplified and faster with less resource consumption.

Globally the 200 years old company boasts of building over 180,000 houses, covering 290,000 roofs, laying 745,000 km pipes, and paving 17,000,000 m2 surfaces in 2018 alone. As far as its Asian footprint is concerned, Wienerberger launched its first operation in 2009 in India wherein the company started production of its Porotherm smart clay bricks out of its Kunigal factory. Since its operation in India, the company has built more than 45,000+ apartments across South India and 15,000 independent houses in addition to building many other prominent and prestigious hospitality and educational institutions.

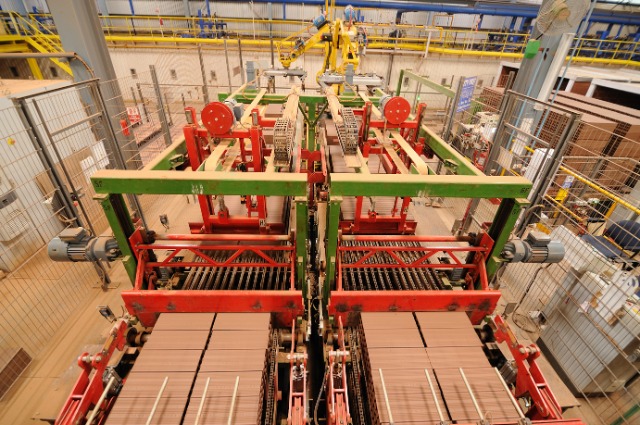

The Kunigal factory affirms usage of state-of-the-art technology like Robotics and has extremely energy-efficient manufacturing processes. The factory is also highly equipped with a full-fledged in-house laboratory and product development facilities. Currently Wienerberger employs about 250 employees in India. The company is also strongly associated with several CSR activities like providing primary healthcare facilities and affordable housing in the vicinity of the factory.

Christof Domenig, CEO, Clay Building Materials Europe, Wienerberger AG, said, “The investment in our Kunigal factory operations will include converting from solid fuel to a cleaner and sustainable energy source – that is natural gas. When it comes to using electrical energy in the factory, 95 percent of the factory requirement is met through renewable energy sources of solar and wind.” Despite there being no such mandate, the measure to introduce natural gas as a fuel is a decision taken by Wienerberger proactively to ensure drastic reduction in carbon emission, although it will incur additional cost for the company. “Wienerberger is continuously striving to convert its production processes to low-emission energy sources.,” adds Christof.

The company is also constantly looking at new growth opportunities in the Indian market including the launch of new sustainable and future-ready solutions for construction. Monnanda Appaiah, MD, Wienerberger India, adds, “In the last 10 years, despite volatility in real estate market, our plant has always run full capacity. That itself is a proof of the value that our solutions bring to our customers. With the INR 30 Crore investment we will also be upgrading our machinery and install new equipment with latest technology that will enable us to scale up the production by up to 25%.” The products manufactured in Kunigal offer significant technical advantages over conventional walling materials apart from being environmentally friendly and cost effective.

Wienerberger’s India product portfolio currently includes clay building materials solutions for walls, roofs, and façades. Wall solutions include products like Porotherm HP, VP Load Bearing, Thermobrick, HP Grinded + Dryfix System; Roof Solutions include Koramic and Tondach; and Façade Solutions include Aspect. “We are also actively marketing and supplying clay roof and façade solutions across India and are also planning to expand the product portfolios for these offerings that would be extremely relevant for the Indian climatic conditions and consumer preferences,” adds Appaiah.